How To Remove Jets To Clean Them In A Small Bath Whirlpool

It is possible that over time, we may observe that the buttons are harder to press or fifty-fifty that the watch button gets stuck if a lot of dirt accumulates.

Necessary tools

First of all, we will need a number of tools to be able to perform the operation smoothly:

- Jaxa key or screwdriver to open the watch.

- Flathead screwdriver.

- Container with soap and water.

- Needle and toothbrush and interdental brush

- Oilers or stick to apply the silicone grease.

- Silicone grease.

Opening the watch case

First, we must open the watch example and then that nosotros tin can disassemble and make clean the buttons properly.

If the watch comprehend has this kind of indentation, it is a screwed cover, and so we will need a jax primal to open it.

If you don't have one, you can try an culling method on how to open up a sentry cover without tools.

How to remove the push button from a sentinel

Once the watch case is opened (either a screwed or screwed cover), the module or movement must be advisedly removed. It is very convenient to take pictures with the mobile telephone, in order to accept a guide of associates and of the dissimilar pieces that we will demand to assemble later.

We must be very careful with certain models of digital watches, as they include small-scale springs that must exist in contact with the back of the watch. If nosotros lose them or exercise not place them correctly, the clock will not work the sound, and the alarms and the hourly beep will cease working.

Once the gown (plastic or metal ring that surrounds the motion to fix it in the box) and the movement are removed, nosotros will proceed to disassemble the buttons.

The outset thing to do is to place the prune that holds the buttons with the opening upwards. In one case placed, with a slice of rod or your finger, we hold it (since they are famous for jumping when removed and lost) and with the edge of the flat screwdriver nosotros push down the clip until it is released.

We save the clip and we tin release the button on the box.

As we can see in the following image, each button usually has a spring, a washer and one or ii gaskets

In some Casio models, the adjustment buttons have the particularity of having only one joint, instead of two, every bit usual.

Cleaning the push button, seals, washer and spring

We ready the container with a piffling h2o and soap. Nosotros detach the parts of the button, and insert the spring, washer and seals in the needle. And we beginning cleaning with soap and water, rubbing them with the interdental brush.

If on the within of the button we see that it has a lot of accumulated clay and is difficult to remove, we can get out it submerged for a while in a kh7 type grease remover to soften information technology.

We put the jump, washer and joints on a paper towel to dry. After cleaning the push with water and soap, we take advantage of it to remove any residue that may have been left on the inside of the push button and we put it to dry.

Make sure that the stem of the button is not twisted, if so, we must straighten it. With some pliers, very gently and gradually try to straighten information technology to get out it as straight as possible. It is important not to be in a hurry and to do it lilliputian past fiddling, since we can break the stalk of the button and have a more serious problem.

Once the parts of the button are dry, we volition repeat the process with all the buttons of the lookout.

Cleaning the watch case

Once the box is empty, we must clean the holes where the buttons are placed with a toothbrush, h2o and soap. So we will dry it advisedly (including the push holes).

Once the instance is dry out, we will proceed to employ silicone grease to the button holes of the lookout man example. Nosotros apply a small amount with an oiler or a toothpick.

Push button assembly

At this point, we'll have to reassemble the buttons. Remember that the order of assembly of the buttons is bound, washer and gaskets.

Once the push button is mounted we volition proceed to apply a minor amount of silicone grease through the spring, washer and seals to lubricate them.

Nosotros place the push inside the hole in the box, taking care that the stem of the push button coincides with the hole in the box. If nosotros see that it does not match, we must straighten the button shaft, dismount it again.

Now comes the most delicate operation, placing the clip on the button stem again inside the box. We identify it on the button shaft with the opening facing down.

With a little scrap of rolling, we hold the clip in this position so that information technology does not escape. Now, with the screwdriver, we push downwards on the edge of the prune until we hear a "click". We must exist careful with the screwdriver so that information technology does non escape by damaging the inside of the instance or the glass.

Nosotros have advantage of the magnifying glass to check that the prune is correctly placed and check that the button is correctly pressed.

Nosotros repeat the process for each button, taking intendance in example the adjustment button is smaller, as it happens in some models, to insert it in its correct place.

Waterproof button exam

One time the buttons are mounted, I like to bank check that everything is correctly assembled by doing a "home" waterproofing test.

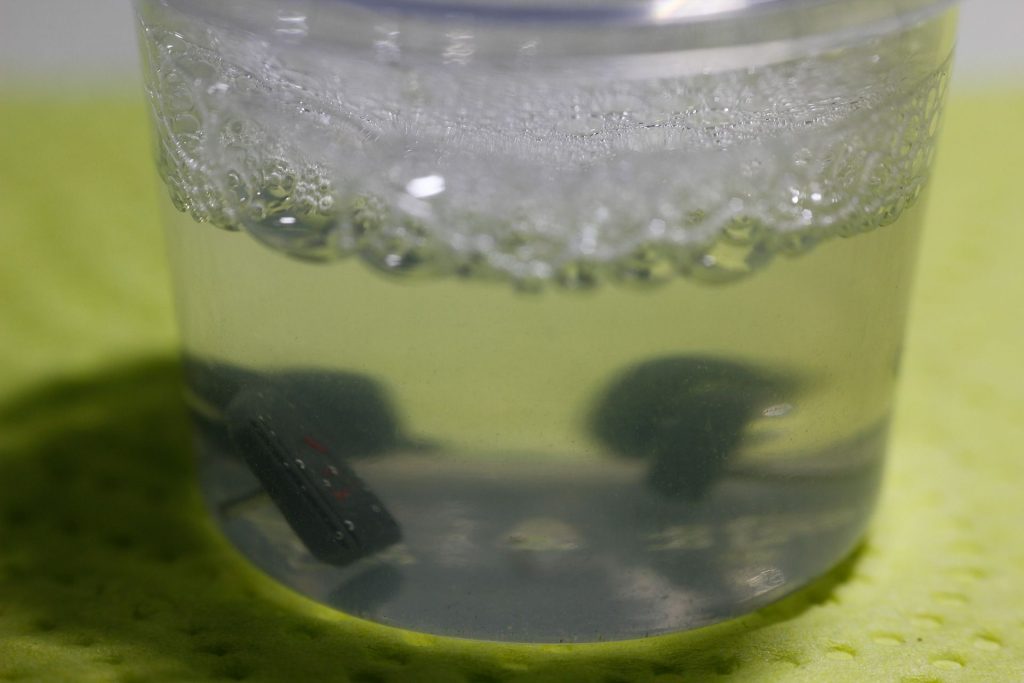

We mount the gasket and the back cover, tightening them with the jaxa central again until the picket box is airtight. This "homemade" waterproofing test consists of submerging the case in water then directing the water jet over the buttons to cheque that no water enters.

Obviously, it never replaces a professional waterproofing exam, only it tin can give usa an idea that the assembly is right and the seals volition withstand at least a niggling soaking.

If nosotros want to accept a bath with the lookout man, nosotros should make certain with a watertightness test carried out by a professional watchmaker, where the advisable mechanism is used and the sentinel is submitted to enough pressure to check its correct watertightness.

In one case it has been checked that no water has entered the lookout instance, nosotros volition proceed to put the sentry calibre in and check the right functioning when pressing the buttons. Place the gown and the sound leap if you lot have one.

Finally, nosotros apply silicone grease to the gasket of the back cover, identify information technology correctly and shut the picket instance with the back cover, without the back gasket coming out of its position.

With this we can at present conclude the cleaning and greasing of the watch buttons.

Source: https://watchrepairblog.info/removal-cleaning-greasing-buttons/

Posted by: mundyacto1941.blogspot.com

0 Response to "How To Remove Jets To Clean Them In A Small Bath Whirlpool"

Post a Comment